2023/10/11

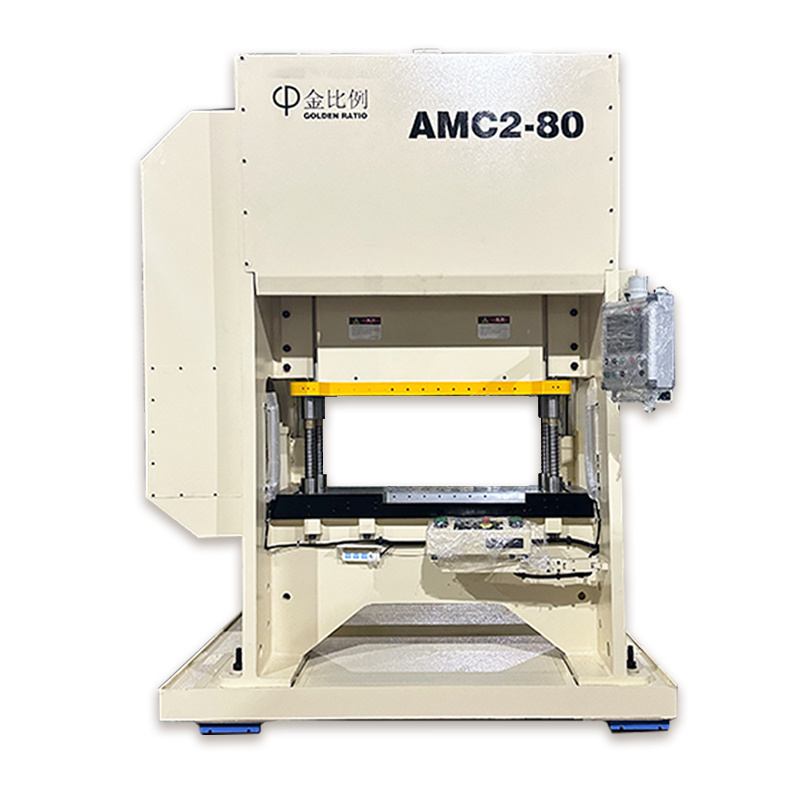

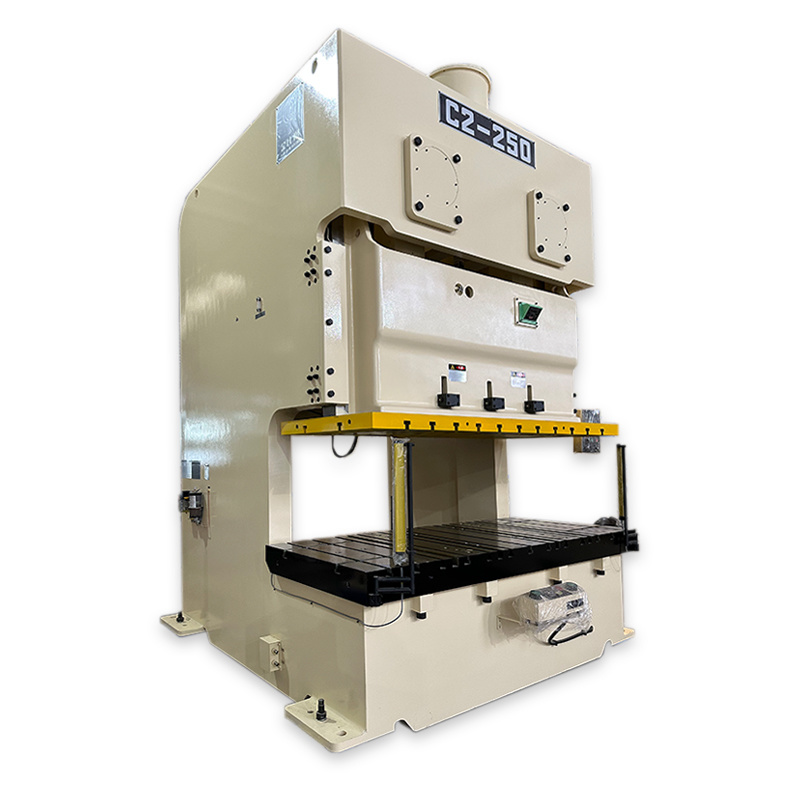

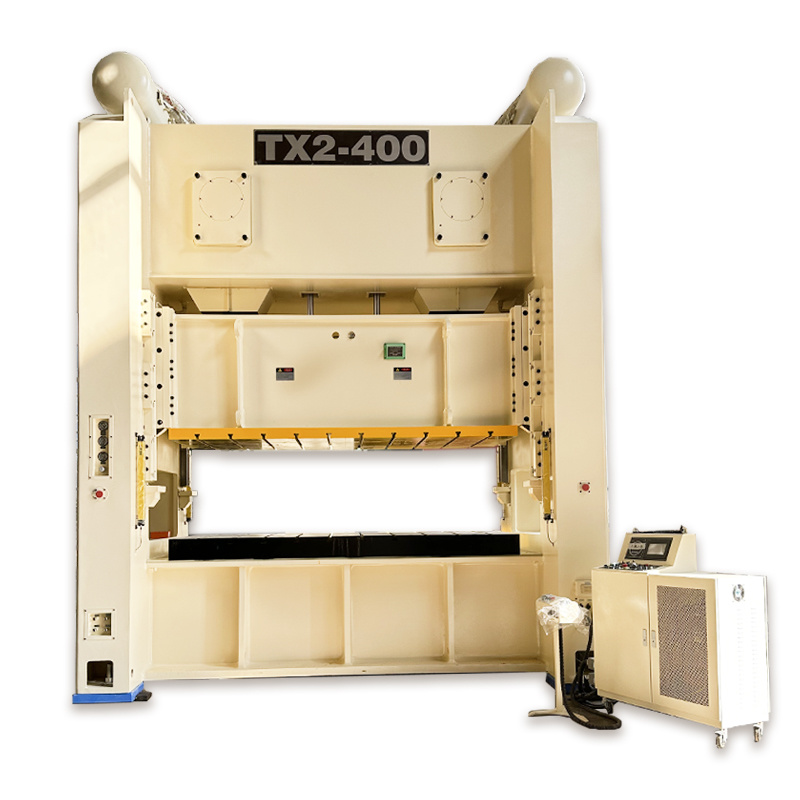

What are the common types of punch equipment?

Punch is a stamping press, stamping is the use of punch through the mold, can make blanking, punching, forming, drawing, trimming, fine blanking, shaping, riveting and extrusion parts. Stamping process because of the traditional machinery to save materials and energy, high efficiency, the operator's technical requirements are not high and through a variety of mold applications can make mechanical processing can not reach the product these advantages. Punch processing is widely used in various fields, such as our switch sockets, cups, cupboards, dishes, computer chassis, and even missile aircraft.

2023/10/11

Now why the cost advantage of mechanical renovation is becoming more and more obvious

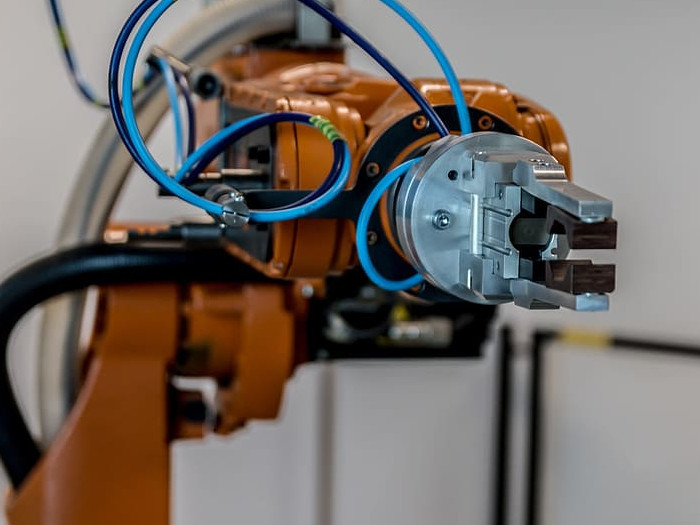

The mechanical paint renovation industry can replace people in production to do some monotonous, repeated and repeated long-term work, or work in dangerous and harsh environments, such as stamping, pressure casting, heat treatment, welding, painting, plastic product forming, mechanical renovation processing and simple equipment, as well as in some areas such as the atomic energy industry, to end the transfer of harmful materials or skill operations.

2023/10/11

What is the use of antirust paint for mechanical equipment painting renovation paint renovation

Paint renovation is suitable for all ferrous materials, spraying and dipping. Nitrite and nitrate free.

2023/10/11

Reasons for the Limited Development of Welding Manipulator Technology Level

The advantages of using welding manipulator is very obvious, not only can improve productivity, reduce labor intensity, but also adapt to the needs of large-scale production, and meet the requirements of cleanliness and hygiene.

2023/10/11

Rigid automated welding equipment Rigid automated welding equipment can also be called primary automated welding equipment, most of which are designed according to the principle of open loop control. Although the entire welding process is automatically completed by the welding equipment, the closed-loop feedback system cannot be used for the fluctuation of welding parameters during the welding process, and the possible deviation cannot be corrected randomly.

2023/10/11

What are the types of welding equipment?

Welding equipment refers to the equipment required to achieve the welding process. Welding equipment includes welding machines, welding process equipment and welding aids.

2023/10/11

Selection principle of welding equipment

If it is thick and large welding, you can use electroslag welding machine; if it is a bar butt, you can choose cold welding machine and resistance butt welding machine. For active metals or alloys, heat-resistant alloys and corrosion-resistant alloys, inert gas shielded welding machines, plasma arc welding machines, electron beam welding machines, etc. can be selected according to specific conditions.

2023/10/11

About welding automation production line repair and maintenance matters!

Automatic production line saves a lot of time and cost. In the city with developed industry, the maintenance of automatic production line has become a hot spot. Automatic production line maintenance mainly depends on the operator and maintenance workers to complete together.