-

About

Located in Chuzhou City, which combines the shape of Wu and Chu, and has a more accurate and vigorou

See More -

-

News

Real time monitoring of our dynamics, constantly changing our relationship with the world

See More -

Service Support

Always prioritize customer interests, meet customer needs, and continuously improve service

See More

Technical Advantages

Energy saving and environmental protection

In the cutting process, the use of CNC cutting system, the use of new cutting gas propane, with high efficiency, low cost characteristics and safety, environmental protection and other characteristics, for thick steel plate cutting, can effectively save energy consumption and reduce costs.

Improve efficiency

In the sanding process and assembly process, more efficient pneumatic grinding machines and pneumatic plates are used to provide high torque output with less consumption, which improves work efficiency and reduces energy consumption.

Multiple technologies

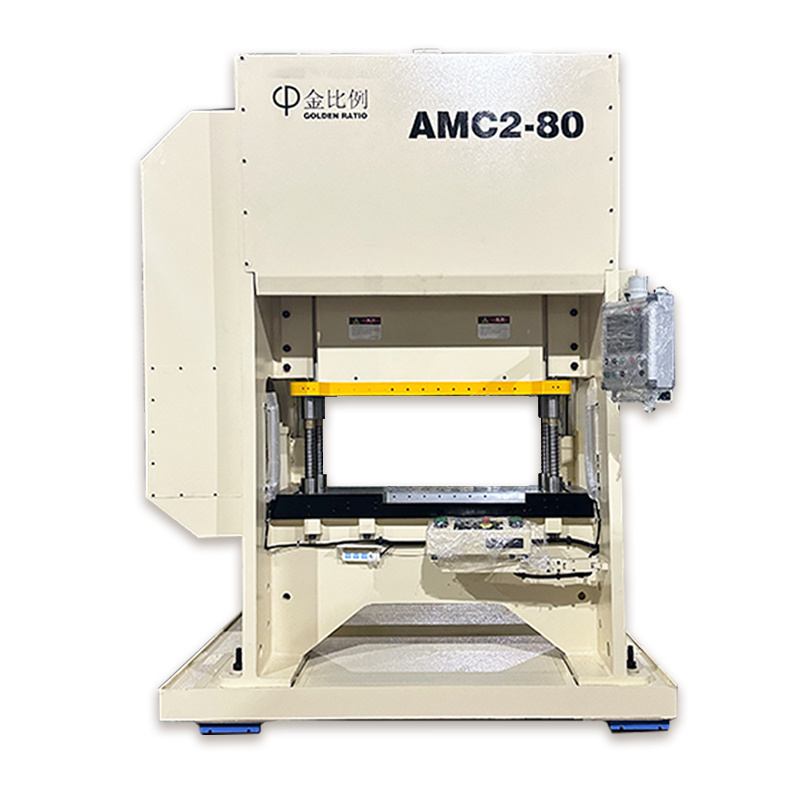

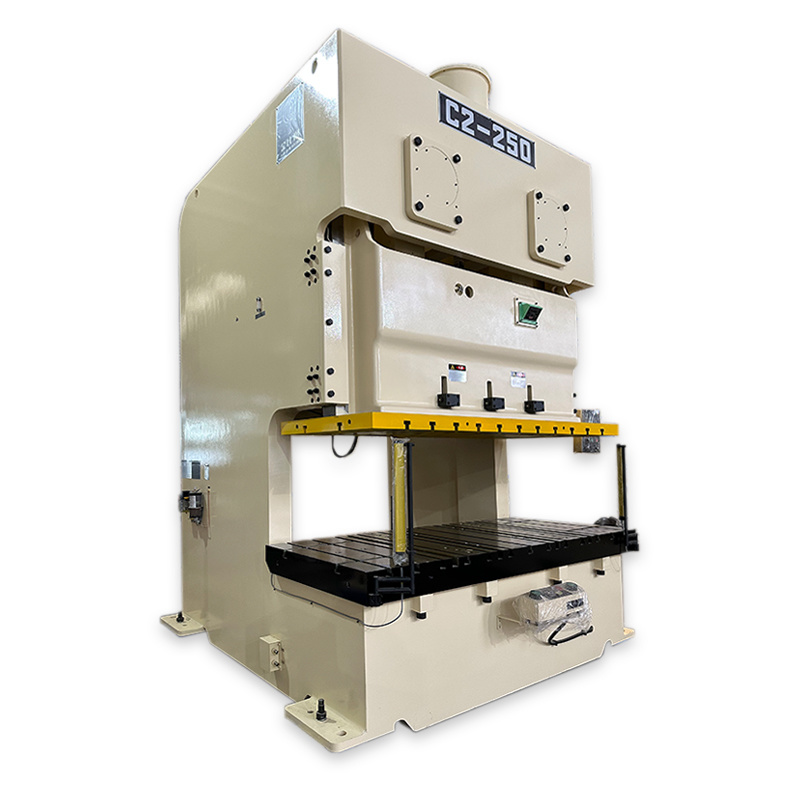

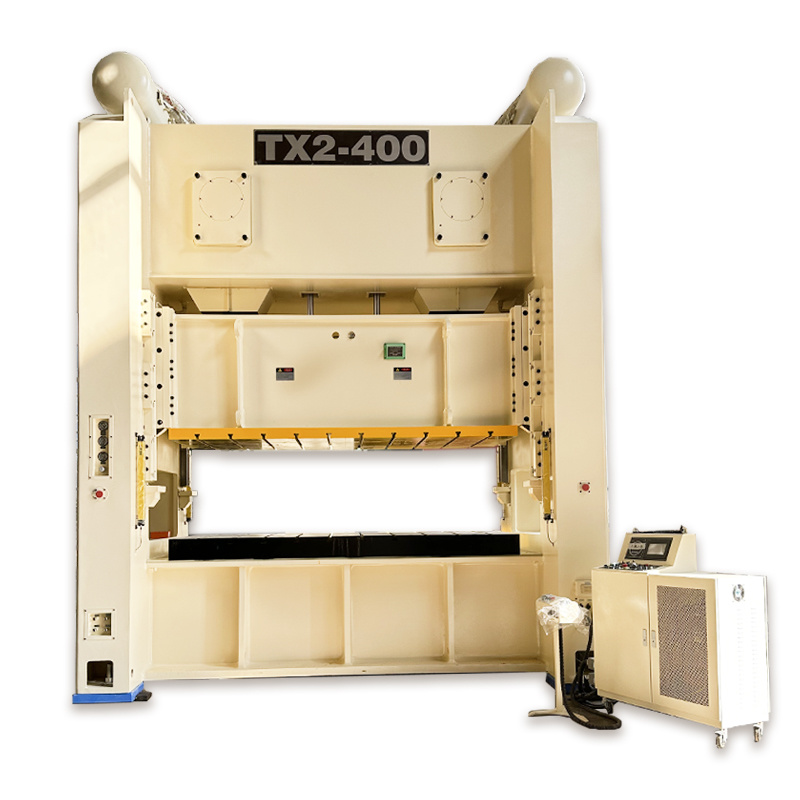

The high-precision high-speed CNC punch produced in this project has two-hand control photoelectric protection technology, pneumatic brake technology, two-degree fall multiple protection technology, automatic feeding technology, the product meets the Japanese JIS1 technical standard, and the material utilization rate can be increased by 4 ~ 8%.

Cost reduction

The energy saving effect of the product is obvious. Compared with ordinary punching machines, a single high-precision high-speed precision punching machine can save electricity by 25 ~ 35%. If each punching machine works 12 hours a day, it can save electricity by 13 kW hours a day, and if it works 308 days a year, it can save electricity by 4004 kW hours a year.

Contact Us

Telephone:

13805847490 / 18757836355

Fax:

0550-8850013

E-mail:

Address:

No.68, Jiashan East Road, Mingguang City, Anhui Province

Tiktok

Kwai

Official Account

© COPYRIGHT 2023 Anhui Golden Ratio Intelligent Equipment Co., Ltd ALL RIGHTS RESERVED | SEO