CT1 Series

The company has automated cutting and welding equipment, large-scale processing equipment, painting equipment and testing equipment.

Classification:

CT1 Series

Hotline:

Precision

Automation

Security

Stable

Energy saving

Environmental protection

- Product Features

- Configuration

- Parameters

- Size

- Download

-

Features

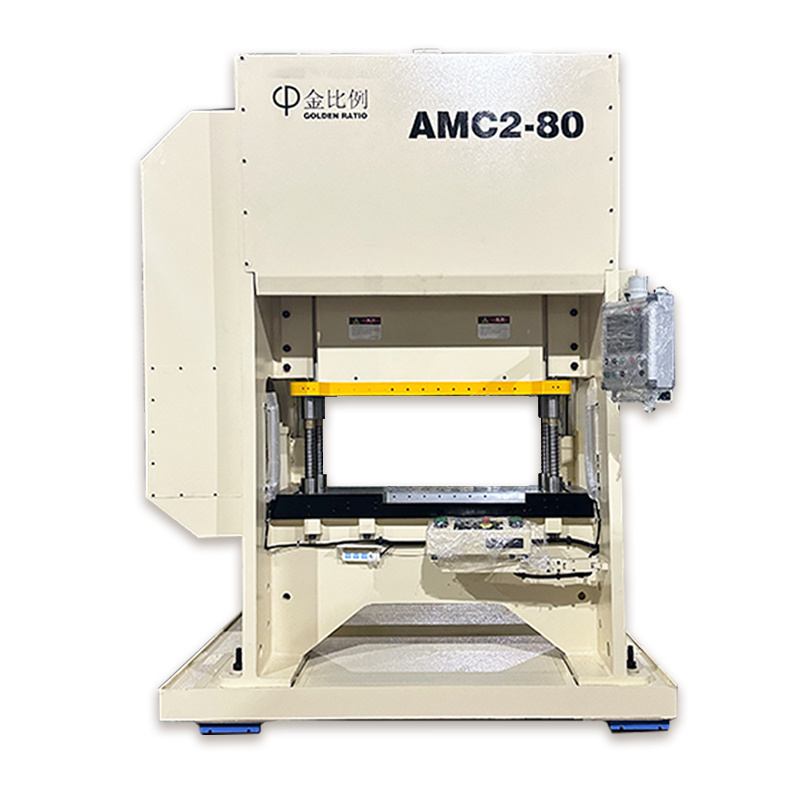

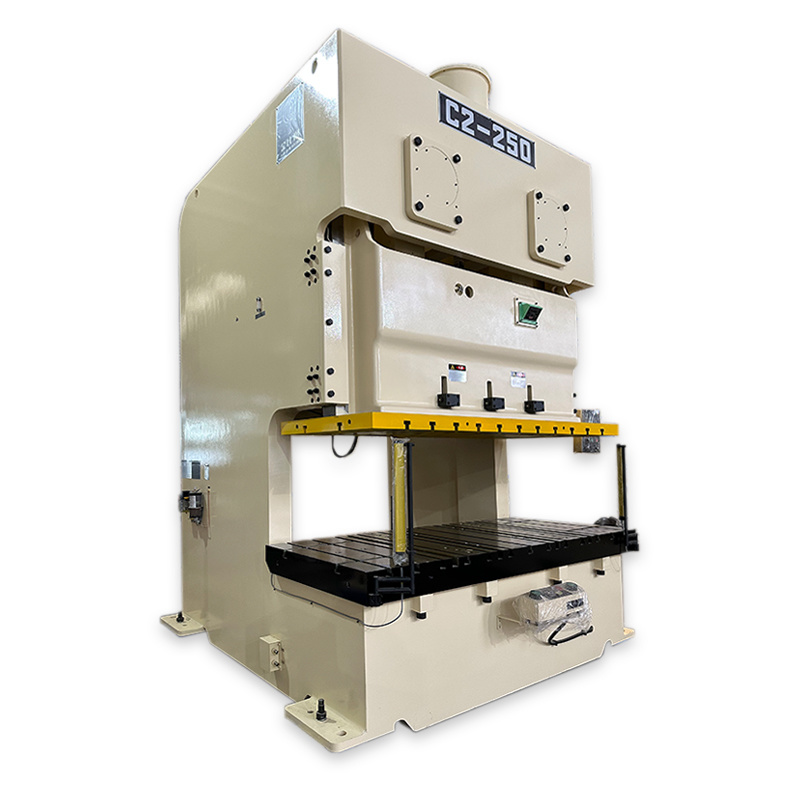

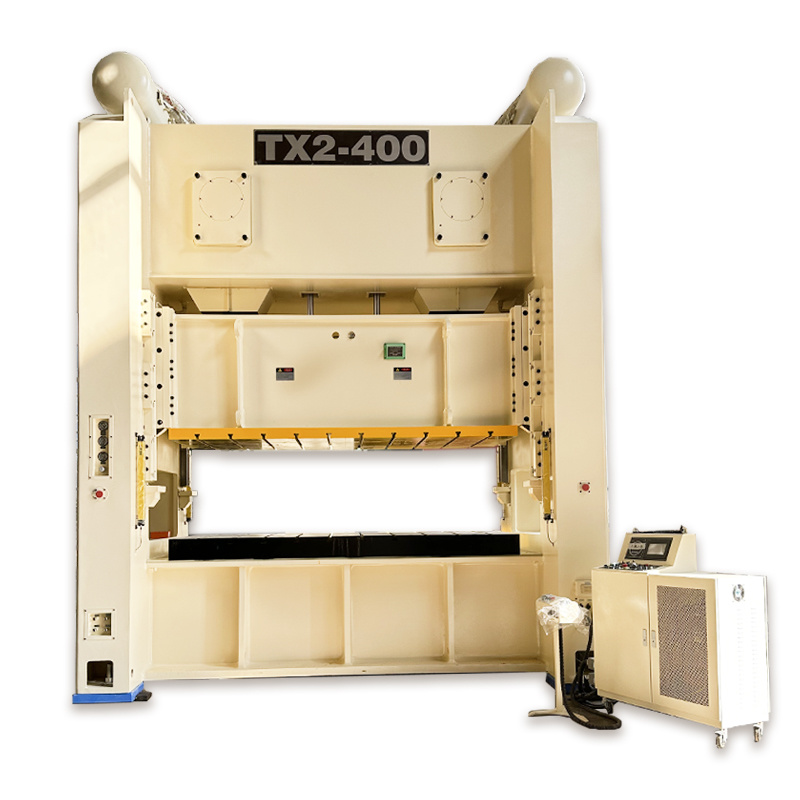

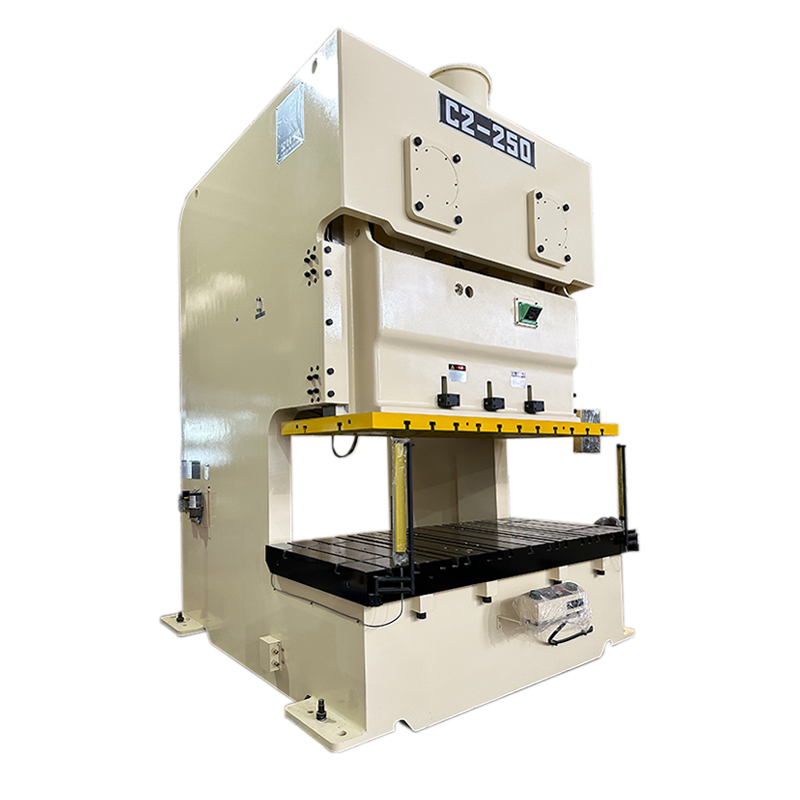

1. Straight wall type integrated frame, suitable for precision continuous die processing.

2. No C- type punch frame open throat shortcomings, can save mold maintenance costs.

3. High rigidity frame, guide rail in the punch center line and long support stroke, small gantry punch can ensure long-term dynamic stability accuracy and extend the life of the mold.

4. The bottom area of the punch is 15 ~ 25% larger than that of the C- type punch, allowing the number of die projects to increase and increase the value-added processing.

5. High torque dry brake clutch, so that the long life of the disc, low maintenance cost; no pollution, low noise, in line with environmental protection requirements. High safety, high affinity, multi-functional electronic control system.

6. Can be matched with various automation equipment, easy to operate.

7. Electric punch adjustment device: This adjustment device uses a thin brake motor and is operated by a button. Its advantages are positioning, stability of the mechanism, and rapid adjustment of lifting.

8. Simple punch adjustment device: simple and reliable manual die height adjustment equipment with a 0.1mm indicator.

9. Electric butter pump: automatic timing centralized lubrication pump and fault detection system to ensure smooth operation.

-

Standard configuration Select Configuration Hydraulic overload protection device Manual grease lubrication device Electric butter lubricating device Air pressure die pad device Frequency converter Quick mold change device (mold lift, mold clamp or mold transfer arm) Electric slide adjusting device Upper feeding device of slide block Electric die height display Misfeed detection device Slider and die balancing device shockproof foot electronic cam switch Photoelectric protection device Air source connector Feeder (air, mechanical and NC types) Second degree fall protection device Rack Maintenance tools and toolboxes leveler Preload counter Manipulator Pre-break counter Left (right) side feeding shaft end Misinformed socket Power outlet Mold lighting device -

Model Unit CT1-80 CT1-110 CT1-160 CT1-200 CT1-260 CT1-315 Type Ton V-type Type H V-type Type H V-type Type H V-type Type H V-type Type H V-type Type H Long stroke mm 150 70 180 80 200 90 200 100 250 150 Number of trips S.P.M 35-80 80-120 30-60 60-90 20-50 40-70 20-50 50-70 20-40 40-50 Ability occurrence point mm 4 2 6 3 6 3 6 3 7 3.5 Closed working height mm 340 380 360 410 460 510 460 510 500 550 Slider adjustment amount mm 80 80 100 100 120 Area of upper table mm 560*420*70 650*470*80 700*550*90 850*630*90 950*700*100 Area of lower table mm 740*550*90 880*600*110 960*800*140 1120*820*160 1200*840*180 Shank hole mm Main motor KW.4P 7.5*4 11*4 15*4 18.5*4 22*4 Slider adjusting mechanism HP Electric Using air pressure Kg/cm² 5-6 5-6 5-6 5-6 5-6 5-6 Punch accuracy CNS(JIS)1Class I Punch (length * width * height) Press mm Die pad (special accessory) One plate, one cylinder One plate, one cylinder One plate, one cylinder One plate, one cylinder One plate, one cylinder One plate, one cylinder Ability Ton 3.6 6.3 10 14 14 Long stroke mm 70 70 80 100 100 Area mm 350*235 410*260 540*350 640*470 640*470

Previous Page

Related Products