-

About

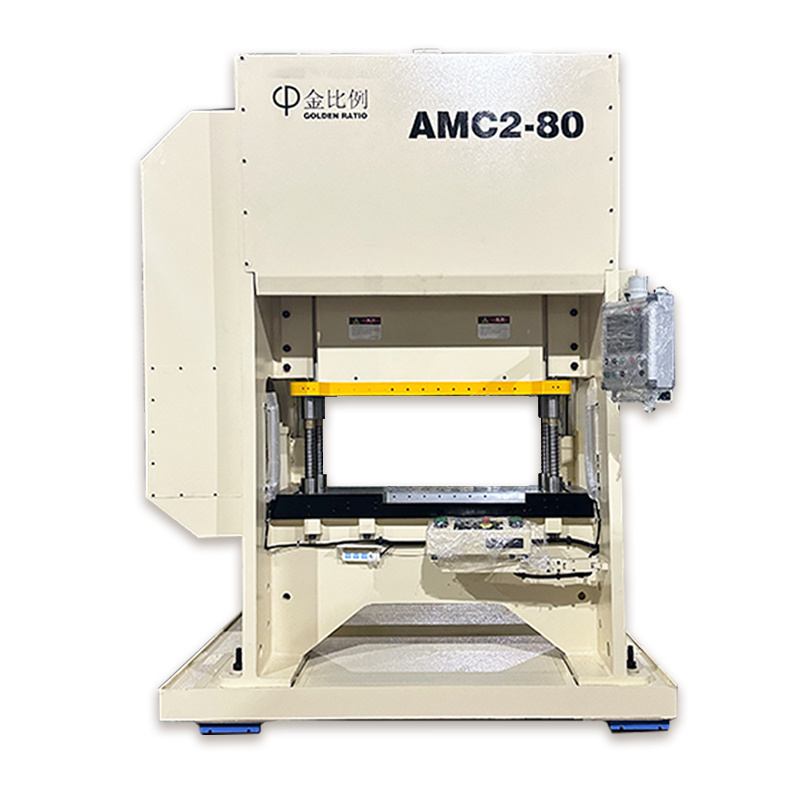

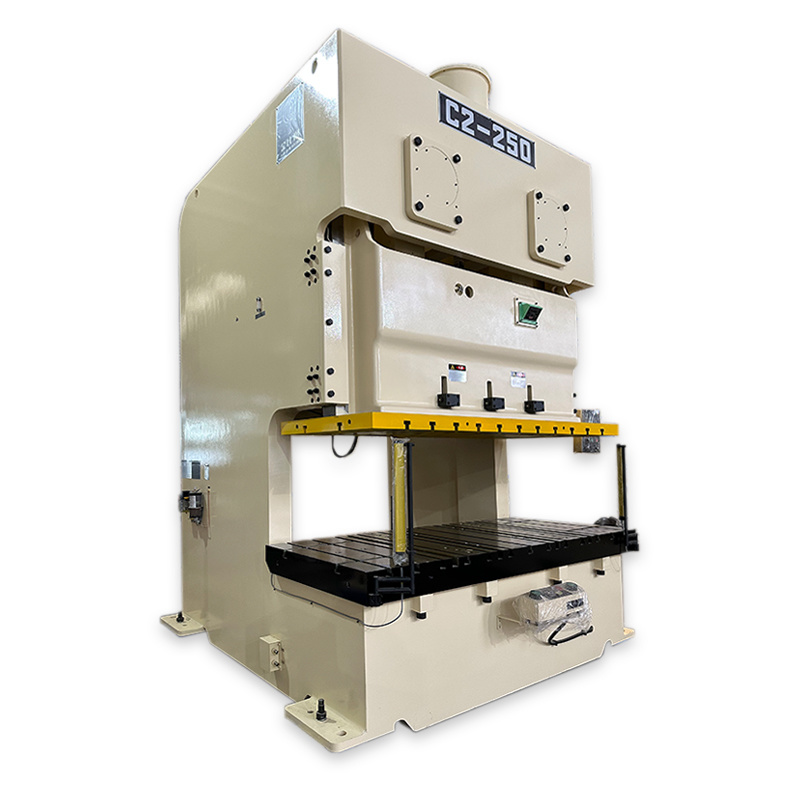

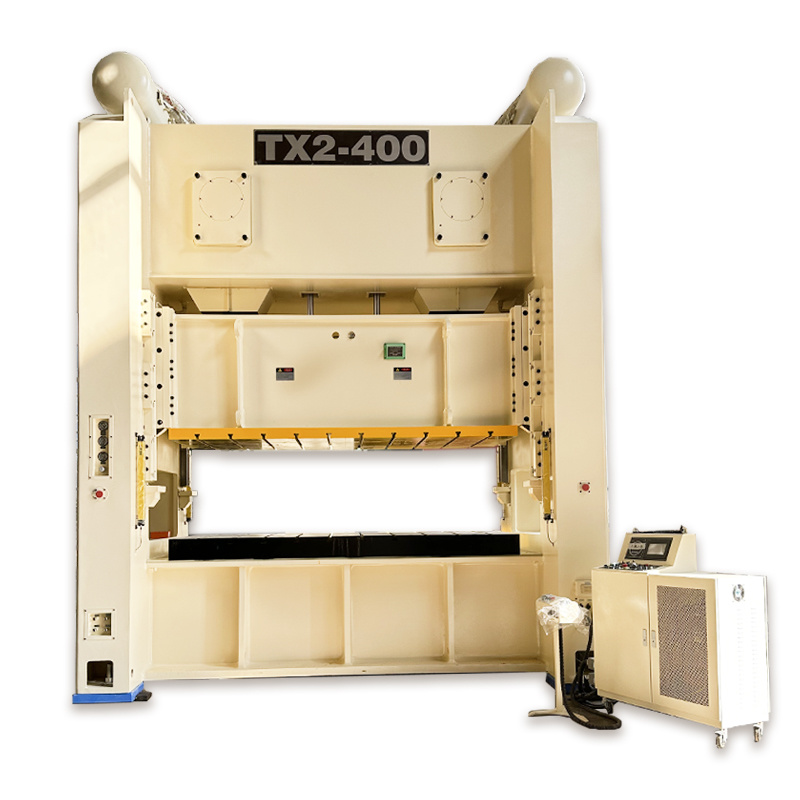

Located in Chuzhou City, which combines the shape of Wu and Chu, and has a more accurate and vigorou

See More -

-

News

Real time monitoring of our dynamics, constantly changing our relationship with the world

See More -

Service Support

Always prioritize customer interests, meet customer needs, and continuously improve service

See More

About welding automation production line repair and maintenance matters!

Release time:

2023-10-11

Source:

maintenance of welding automation production line:

Automatic production line saves a lot of time and cost. In the city with developed industry, the maintenance of automatic production line has become a hot spot. Automatic production line maintenance mainly depends on the operator and maintenance workers to complete together.

Two methods of automatic production line maintenance:

Synchronous repair method: in production, such as the discovery of failure as far as possible not to repair, to maintain the method. Make the production line continue to produce to holidays, focus on maintenance workers, operators, for all problems, repair at the same time. The equipment was in full production on Monday.

Divisional repair method: automatic production line if there is a big problem, repair time more often. The synchronous repair method cannot be used. At this time, the use of holidays, centralized maintenance workers, operators, a part of the repair. Until the next holiday, the other part will be repaired. Ensure that the automatic production line does not stop production during working hours. In addition, as far as possible in the management of the use of pre-repair methods. Install a timer in the equipment, record the working time of the equipment, apply the wear law to predict the wear of wearing parts, replace the wearing parts in advance, and eliminate the fault in advance. Ensure full production line.

Maintenance of welding automation production line:

Circuits, gas circuits, oil circuits and mechanical transmission parts (such as guide rails, etc.) shall be inspected and cleaned before and after work. The work process should be inspected, key parts should be inspected randomly, and any abnormal problems should be recorded. Small problems should be handled after work before work (time is not long), and parts should be prepared for major problems. Unify the whole line of shutdown and maintenance, make plans for wearing parts, replace wearing parts in advance, and prevent unburnt.

Next Page

Related News

Contact Us

Telephone:

Fax:

0550-8850013

E-mail:

Address:

No.68, Jiashan East Road, Mingguang City, Anhui Province

Tiktok

Kwai

Official Account

© COPYRIGHT 2023 Anhui Golden Ratio Intelligent Equipment Co., Ltd ALL RIGHTS RESERVED | SEO