Structure and technical characteristics of servo press

Release time:

2023-10-11

Source:

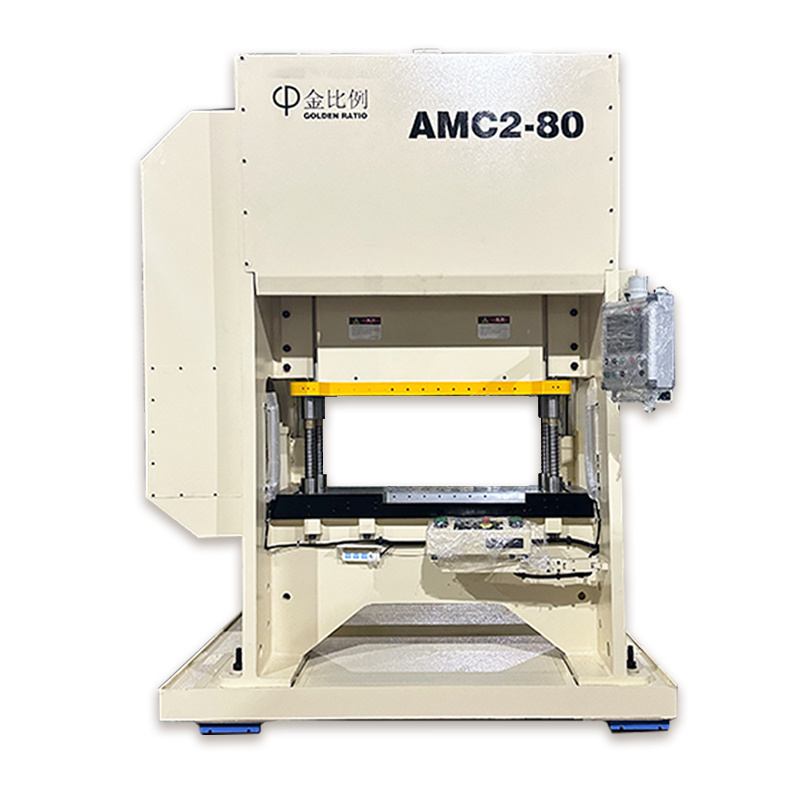

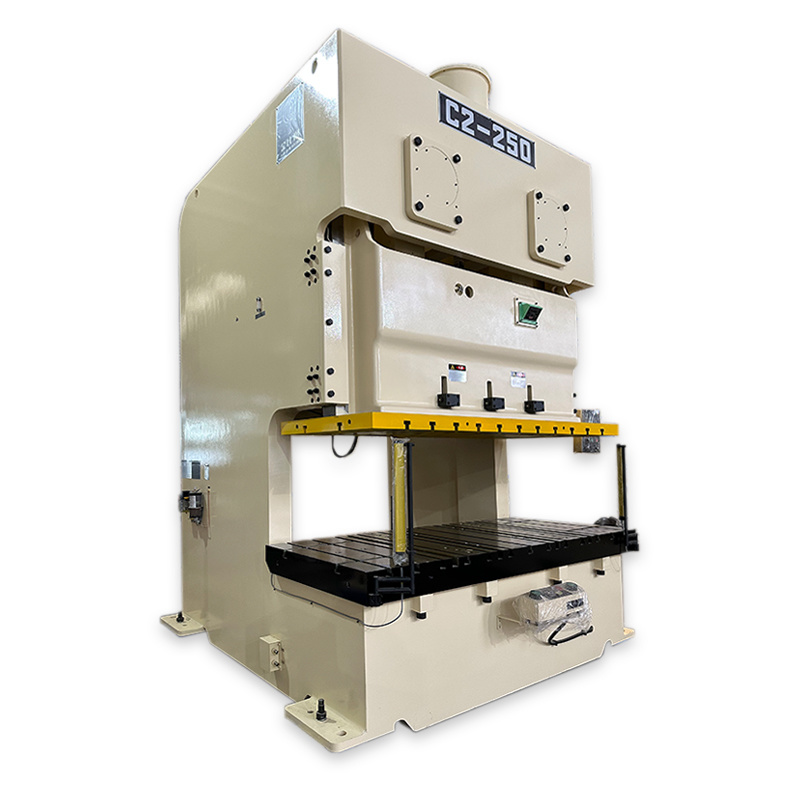

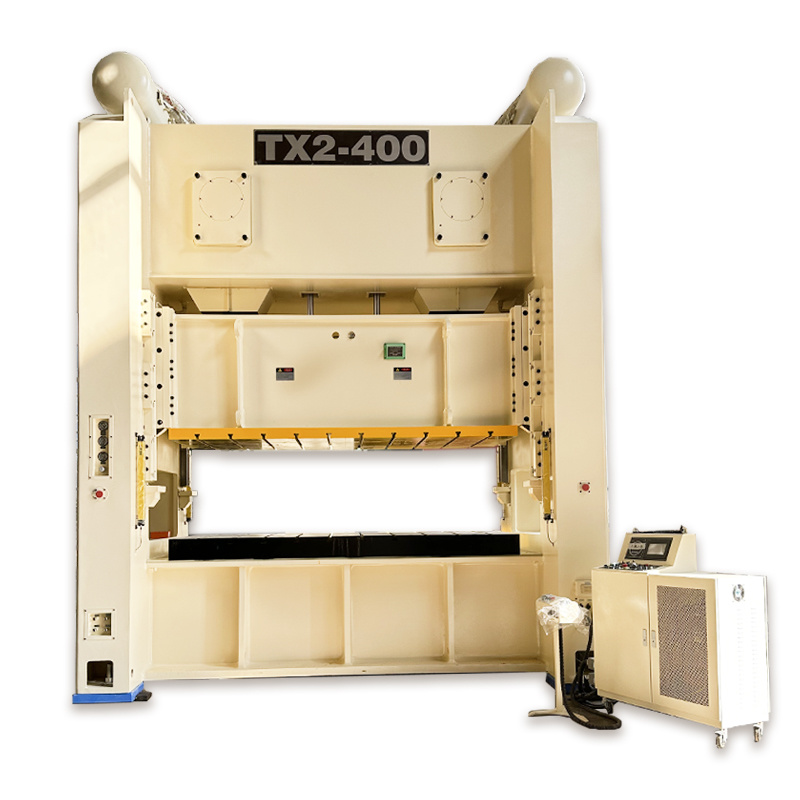

1, the main structure: the use of table-type structure, simple and reliable, strong bearing capacity, bearing deformation is small, is a stable, wide range of applications of the bearing structure.

2. Servo press system composition:

The main system composition of the equipment: servo press-fitting unit, control system, display and other components.

The principle of servo press-fitting: the servo motor drives the precision ball screw through the synchronous belt to realize the precise position control of the pressure spindle; The front end of the pressure spindle is equipped with a highly sensitive pressure sensor, which can detect the load of the pressure spindle in real time. The control system collects position and load data in real time, thus realizing the online quality management technology of precision press-fitting.

3. Servo press-fitting unit mainly consists:

Drive device --- servo drive

Transmission device --- synchronous wheel structure, precision ball screw (grinding grade)

Pressure output --- pressure spindle (hard chrome plating)

Bearing suit-ball bearings, self-lubricating bearings, etc.

Pressure sensor --- external type, beautiful structure, no wire interference

Shell-sheet metal painting (computer white)

Control system-closed loop control

Structure and technical characteristics of servo press

4. Detailed description of display interface of servo press control system:

1) The control system is based on the Japanese Yaskawa servo controller, imported brand, and quality assurance. Equipped with 7-inch true color touch display, full Chinese interface, graphic display, touch operation, simple and intuitive, ordinary operation staff can be on duty after simple training.

2) equipment operation, debugging, all parameters can be directly written on the man-machine screen; teaching mode (parameter setting state), you can manually run the equipment to the operation position, and then directly write the current value.

3) Equipped with USB communication interface, equipment-related press-fitting data can be exported to PC with USB disk and opened in Excel format for storage, editing and product quality traceability.

4) Three press-fitting modes can be selected:

Position mode: constant speed, set the absolute position to reach the press-fit stop;

Pressure mode: constant speed, relative pressure reaches press-fit stop;

Displacement mode: constant speed, relative displacement reaches press-fit stop;

5) single stroke six speed precise control

Fast Forward: Fast Approaching Workpiece

Detection: detection travel before no load to load

Press-fit: contact the workpiece and start to press-fit.

Buffer: deceleration before pressing in place

Pressure holding: retention time when pressing in place

Return: Quickly return to the work origin after the pressure holding completion point

6) servo press, servo drive mechanism can be inching, single step, automatic operation. Online quality determination function: can realize synchronous detection of press-fitting. No additional detection station, you can easily achieve the full inspection of the product.

7) When the quality is NG or the equipment is abnormal, the equipment will automatically stop running, and the sound and light will report the alarm, waiting for manual processing.

8) Self-diagnosis function: when the equipment fails to alarm, the man-machine can display the alarm reason and the suggested treatment method to facilitate the maintenance personnel to quickly eliminate and solve.

9) Safety protection: the equipment has over-travel, overload and over-setting alarm functions. Three-color lamp post plus buzzer sound and light alarm. Equipped with emergency stop button, press the emergency stop button in case of emergency, the equipment will stop running and sound and light alarm to avoid accidents.

10) The servo press system is a new version of the manufacturer's standard mature control system. The configuration conforms to the ergonomically designed operation control panel.

5. Operation flow of servo press:

1) After checking that the equipment is abnormal, turn on the power and the equipment enters the initial reset state. After the reset is completed, the equipment enters the standby state, and the three-color status indicator is green;

2) Put the workpiece to be pressed on the workbench.

3) Select the mold number to be pressed on the operation interface of the man-machine display screen; Switch to "automatic/single cycle" mode in the selection button, then press the start button on the button box with both hands at the same time, and the equipment starts to run. The three-color lamp is yellow operation indication.

4) The pressure spindle starts to act at the set speed: quick down-detection-press fitting-buffer-pressure maintaining-return.

5) After the press-fitting is completed, the three-color status indicator of the equipment turns green;

6) After the selection button is switched to the "manual" mode, that is, after the two-hand trigger is started, the servo pressure spindle goes down and stops when it is released. This action is mainly used for equipment debugging and initial alignment of the workpiece.

7) Status when pressing the emergency stop button:

The three-color light is red; the buzzer continuously emits a short beep; the pressure spindle stops at the current position; press the "reset" button to return the pressure spindle of the equipment to the origin of work and stand by until the equipment is pressed to start again.

6. The servo press adopts AC servo motor drive device to provide a clean working environment. Compared with pneumatic and hydraulic equipment, the servo press can save about 80% of energy, which meets the special requirements of different clean workshops. It has the characteristics of environmental protection, energy saving, safety and low operating cost.

Related News