-

About

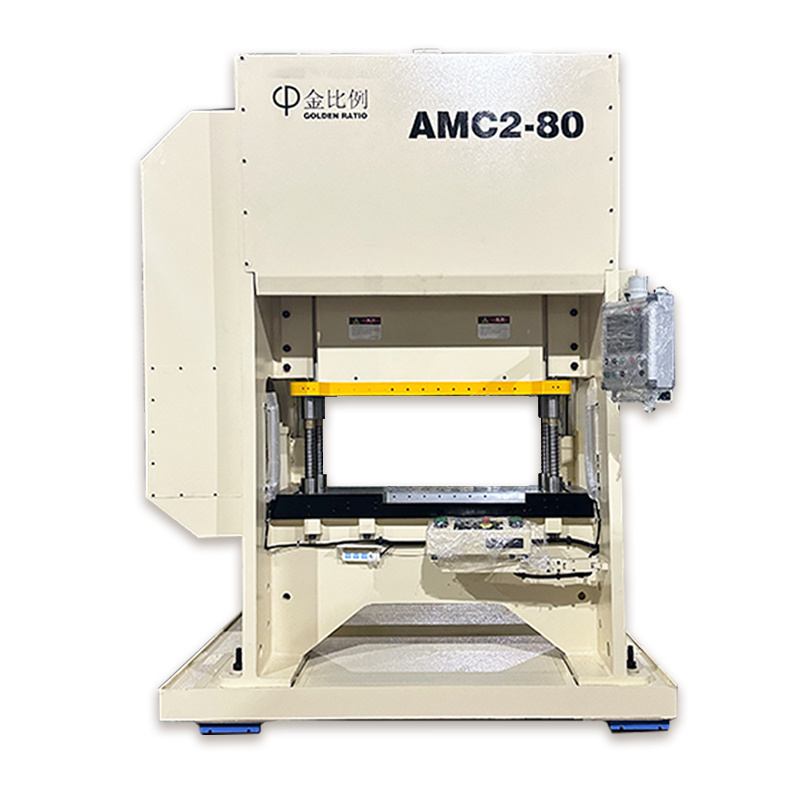

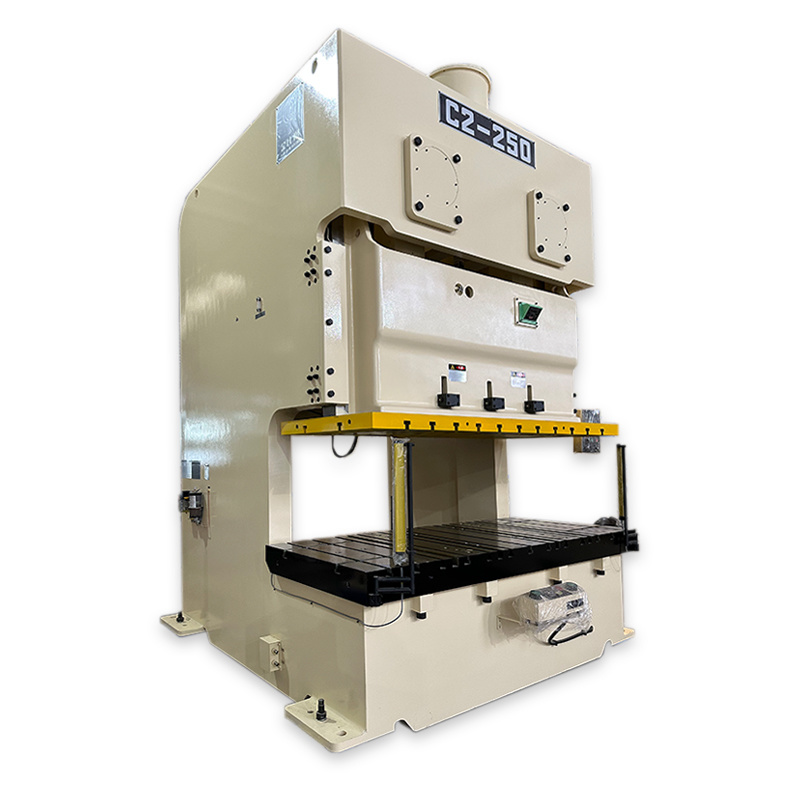

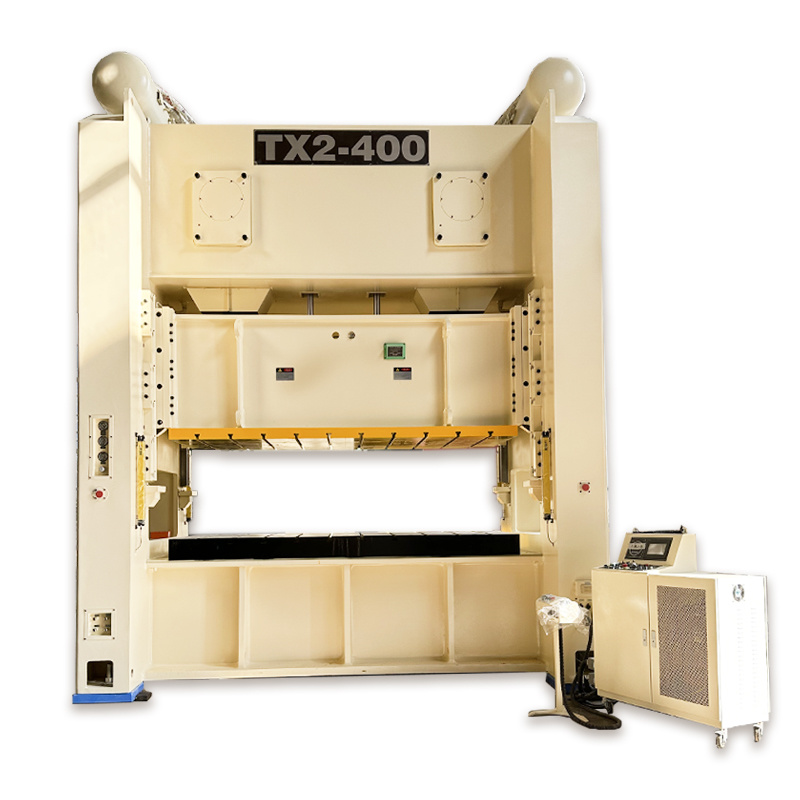

Located in Chuzhou City, which combines the shape of Wu and Chu, and has a more accurate and vigorou

See More -

-

News

Real time monitoring of our dynamics, constantly changing our relationship with the world

See More -

Service Support

Always prioritize customer interests, meet customer needs, and continuously improve service

See More

What should we pay attention to in the process of machine tool renovation?

Release time:

2023-10-11

Source:

1, do the preparatory work for machine tool renovation, personnel allocation and material preparation.

2, in the process of painting renovation, pay attention to which parts of the machine tool need to be renovated, but also pay attention to the painting process can not affect the later use of the machine tool.

3. Another important safety link of the machine tool is to prevent cold start of the pre-plastic screw. When the material of the screw does not reach the specified temperature and heat preservation time, it is prohibited to start or an alarm will occur. Machine tool nozzle splash material protection device is necessary to prevent burns.

The first step in the renovation of the machine tool is to remove rust. There are many methods of removing rust. Here are some of the most commonly used methods of removing rust.

Treatment of metal on the surface of machine tool refurbishment and painting:

As far as metals are concerned, there are rust layers, pits, grease, welding slag, moisture, and some old paint films on the surface before painting. If you do not do surface treatment and direct coating, will lead to poor film appearance, and congenital hidden dangers. Such as the coating water resistance, oil resistance, acid and alkali resistance 3 reduced, some quickly peeling, some slowly will produce rust, reduce the film protection and decorative effect. Therefore, it must be dealt with and should not be carried out carelessly.

1. Derusting: including manual derusting, mechanical derusting, sand blasting derusting, chemical derusting.

Manual derusting: with emery cloth, scraper, hammer chisel, wire brush and other tools, with manual knock, shovel, wire brush rust layer, with cotton sand to wipe off rust dust before coating construction.

Machine tool painting mechanical rust removal: with the help of small motors, air tools, such as angle grinding wheel, grinding machine, etc., use its impact and sanding effect to remove rust and dirt. The mechanical rust removal efficiency is high, and it is widely used in the construction site.

Previous Page

Related News

Contact Us

Telephone:

Fax:

0550-8850013

E-mail:

Address:

No.68, Jiashan East Road, Mingguang City, Anhui Province

Tiktok

Kwai

Official Account

© COPYRIGHT 2023 Anhui Golden Ratio Intelligent Equipment Co., Ltd ALL RIGHTS RESERVED | SEO