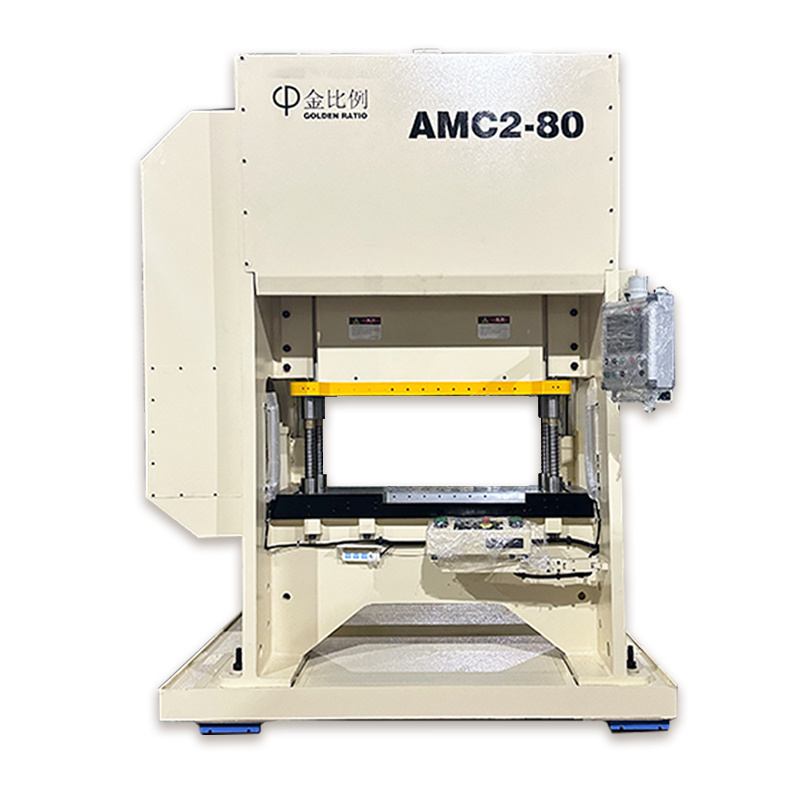

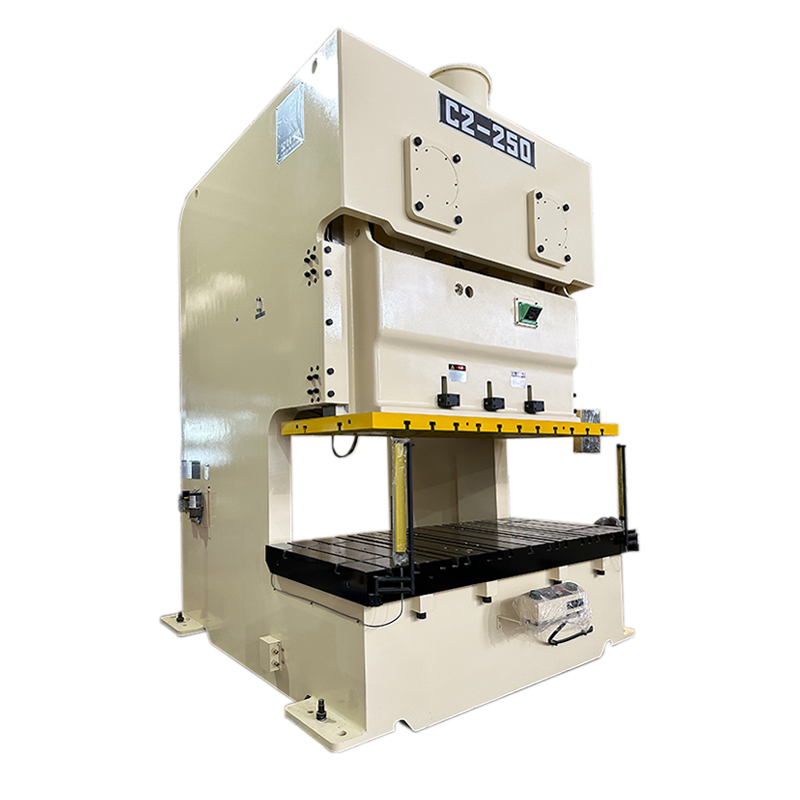

AMC2 Series

The company has automated cutting and welding equipment, large-scale processing equipment, painting equipment and testing equipment.

Classification:

AMC2 Series

Hotline:

Precision

Automation

Security

Stable

Energy saving

Environmental protection

- Product Features

- Configuration

- Parameters

- Size

- Download

-

Ultra-long six-sided guide rail, strong anti-deflection load capacity, good precision and stability

The whole thin oil lubrication, and standard oil pan, equipment clean and tidy

Equipped with guide post guide sleeve thin oil lubrication pump and mold stretching oil pump

Rotatable large touch screen, generous and convenient operation

Configuration of upper and lower template guide column guide sleeve to improve motion accuracy

-

Standard configuration Select Configuration Main motor reversing device SET 1 Mold pad NONE None Hydraulic overload protection device SET 1 SET NONE Electric slide adjusting device SET Photoelectric safety device SET 1 Electric grease lubrication device SET 1 Mold lighting SET 1 Slider and die balance device SET 1 Power socket 1 Electronic cam switch SET 3 Single-phase 11 type two-pole 220V.10A SET 1 Electronic crankshaft angle display SET 1 Single-phase Y-type three-stage 220V.10A 1 Digital die height indicator SET 1 Shockproof foot SET 1 Second fall protection SET 1 T-stand SET 1 Production technology (8 digits) SET 1 Quick mold change Misinspection of metal socket SET 2 Upper Clamp Die 1 Maintenance counter (8 digits) SET 1 Clamp type 1 Programmable controller SET 1 Number of clamps SET 1 Inverter SET 1 Thickness of upper formwork mm 1 Touch Screen SET 1 Lower mold clamp 1 Air blowing connector SET

1

(3/8")Clamp type 1 Air supply connector SET

1

(3/8")Number of clamps PC 1 Safety Net SET 1 Thickness of lower formwork mm 1 Maintenance Tools and Toolbox SET 1 Hydraulic power source model 1 Instructions Clutch brake SET 1 -

Model Unit AMC2-60 AMC2-80 AMC2-110 punch capacity 60 80 110 Ability occurrence point mm 3 3.5 5 Long stroke mm 140 190 190 Closed working height mm 260 320 320 Number of trips S.P.M 50-100 60-80 30-50 Area of upper table mm 1460*480*70 1460*480*70 1760*500*70 Area of lower table mm 1500*480*130 1500*480*130 1800*600*130 Main motor power KW.4P 7.5 11 15

Previous Page

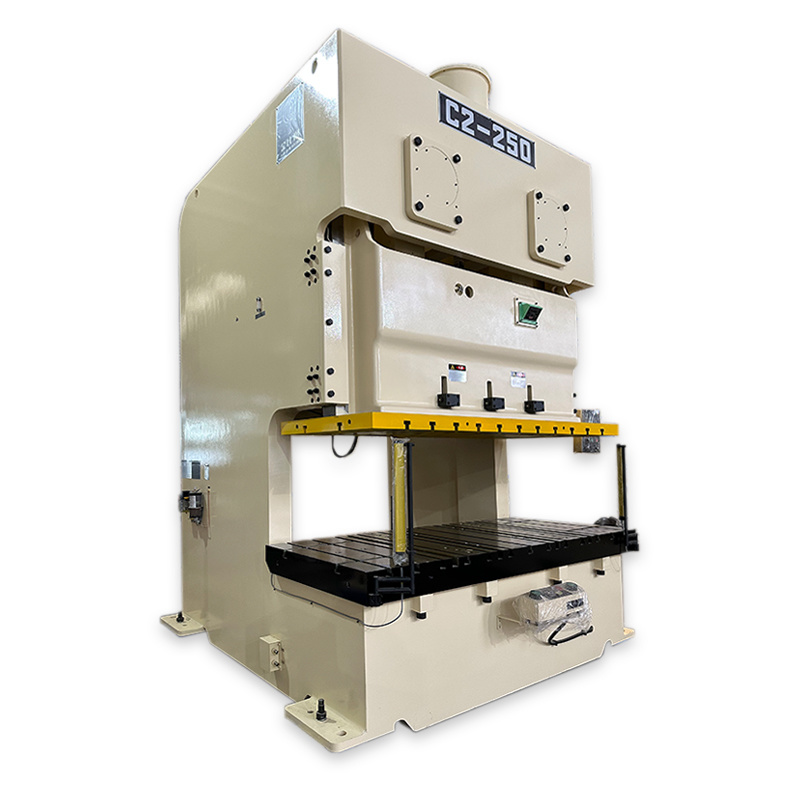

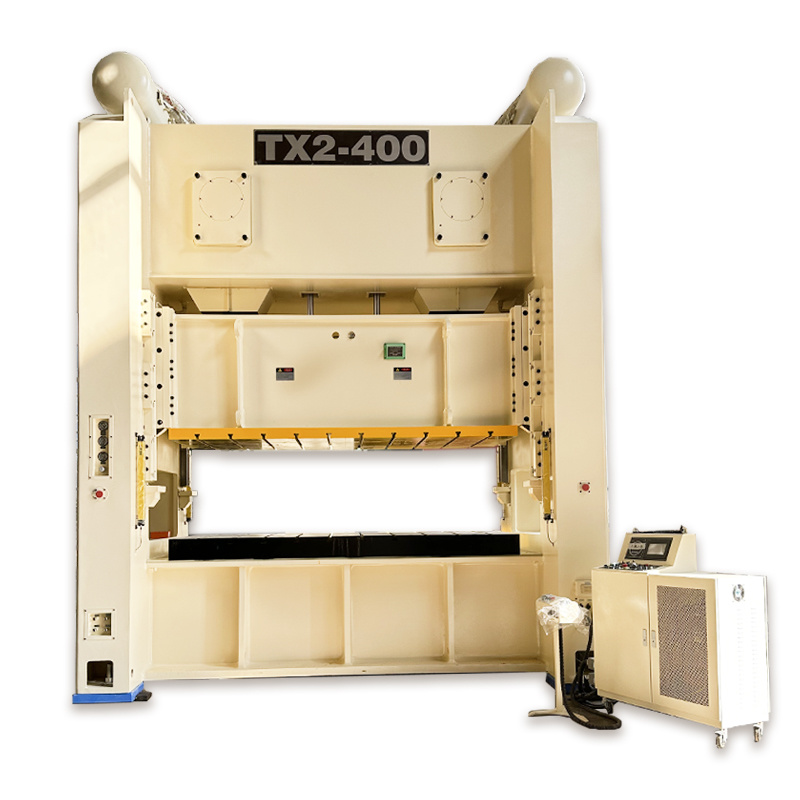

Related Products