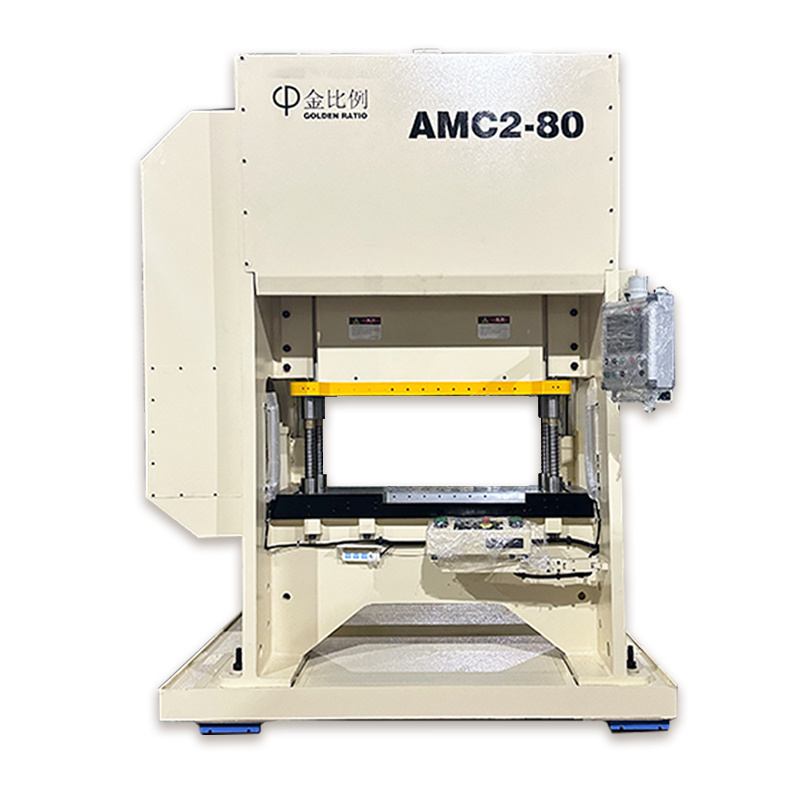

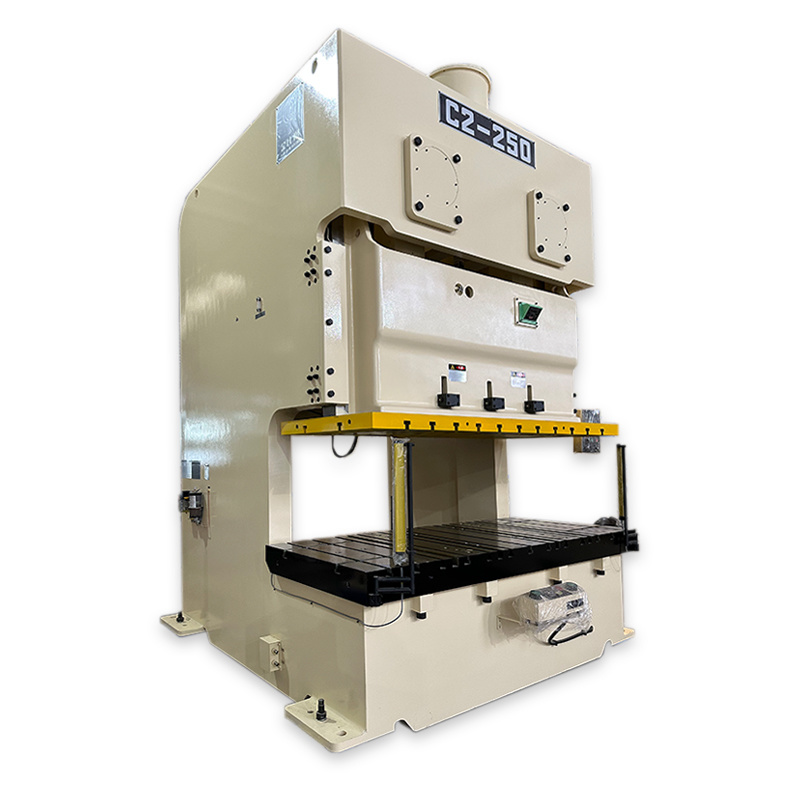

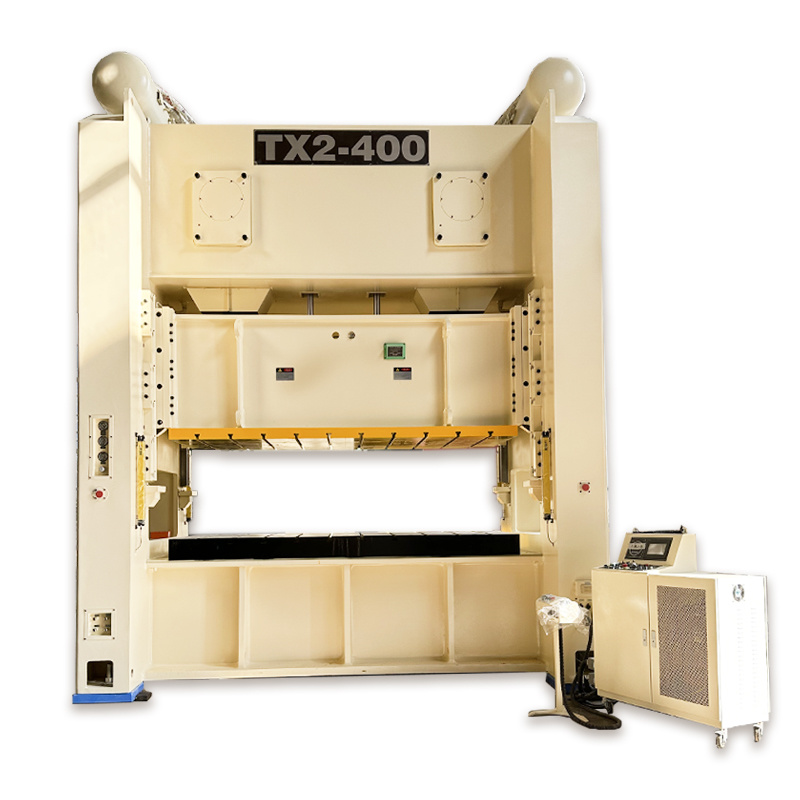

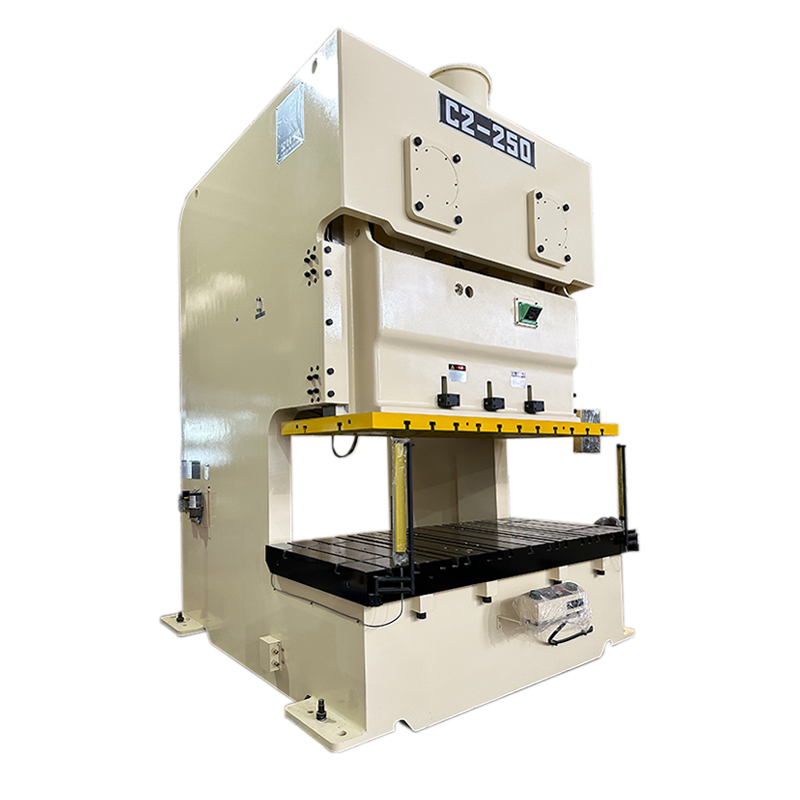

STD Series

The company has automated cutting and welding equipment, large-scale processing equipment, painting equipment and testing equipment.

Classification:

STD Series

Hotline:

Precision

Automation

Security

Stable

Energy saving

Environmental protection

- Product Features

- Configuration

- Parameters

- Size

- Download

-

Features

1. The main parts of the fuselage of the press adopt steel plate welded split structure or steel plate welded integral fuselage structure. The top seat, middle platform body and base in the split structure are pretightened by four reinforcing rods to form a whole body with high rigidity.

2. The press adopts eccentric gear, stable transmission and low noise

3. In the use of four corners of the guide road long guide rail guide, lateral force is small, high precision.

4. The working table of the press can be fixed or forward, backward, left and right, and "T" type movement. Users can choose according to the specific conditions such as equipment layout, single machine or production line. The mobile trolley is convenient and quick to change the mold.

5. The model of the press can adopt air cushion fixed stroke or adjustable stroke to meet the process requirements of various complex structures and parts to be stretched.

The lubrication system of the press adopts automatic circulation system, continuous fixed-point and quantitative oil feeding mode, and has fault detection devices such as pipeline blockage, rupture and insufficient oil.

7. The electrical control system of the press adopts programmable (PLC) control system, but the electronic cam beginning, control angle monitoring and display, pressure monitoring tonnage display and other functions are controlled by PLC.

-

Standard configuration Select Configuration Hydraulic overload protection device Slider automatic adjustment device Frequency converter Balancer air pressure automatic adjustment device Electric slide adjusting device photoelectric safety device digital die height display Upper feeding device of slide block Slider and die balancing device Front moving safety door electronic cam switch Rear moving safety door Air source connector load monitor Second degree fall protection device shockproof device Attached inspection double solenoid valve Mould pad device (as per detail specification) Flywheel brake device (400 tons and above) MOBILE MOBILE (as per detail specification) Mold lighting lamp Quick mold change device (as per detail specification) Safety block and safety bolt Press peripherals (as per detail specification) T-type mobile table (2) Centralized oil lubrication device Independent electric control cabinet Foundation plate and foundation screw Maintenance tools and toolboxes Instructions for use -

Model Unit STD-250 STD-250 STD-300 STD-300 STD-400 STD-400 STD-500 STD-500 STD-630 STD-630 STD-800 STD-800 STD-1000 STD-1000 punch capacity Ton 250 250 300 300 400 400 500 500 630 630 800 800 1000 1000 Ability occurrence point mm 7 7 7 7 9 9 9 9 10 13 10 13 13 13 Long stroke mm 300 350 300 350 300 400 300 400 400 400 400 400 400 400 Number of trips S.P.M 20-35 20-35 20-35 20-35 20-35 20-30 20-30 15-25 20-30 15-25 20-30 15-25 20-30 15-25 Closed working height mm 800 800 800 800 1000 1000 1000 1000 1000 1000 1000 1000 1200 1200 Slider adjustment amount mm 200 200 200 200 250 250 300 300 300 300 350 350 400 400 Side opening size mm 1100*850 1100*850 1100*900 1100*900 1250*1000 1250*1000 1300*1100 1300*1100 1500*1100 1500*1100 1500*1100 1500*1100 1600*1500 1600*1500 Maximum upper die weight mm 1500 2000 1500 2000 3500 4000 4000 5000 6000 10000 10000 12000 10000 12000 Main motor KW*4P 30*4 30*4 37*4 37*4 45*4 45*4 55*4 55*4 75*4 75*4 90*4 90*4 110*4 110*4 Area of upper and lower workbenches 2500*1200 2500*1200 3000*1300 3000*1400 3200*1400 3800*1600 3800*1600 2600*1200 2600*1200 3200*1400 3200*1400 3800*1600 4000*1400 4000*1400 2770*1250 2770*1300 3400*1400 3400*1500 4000*1800 4000*1800 4000*1800 3000*1250 3000*1400 3500*1400 3500*1500 4500*1800 4500*1800 4500*1800

Previous Page

Related Products