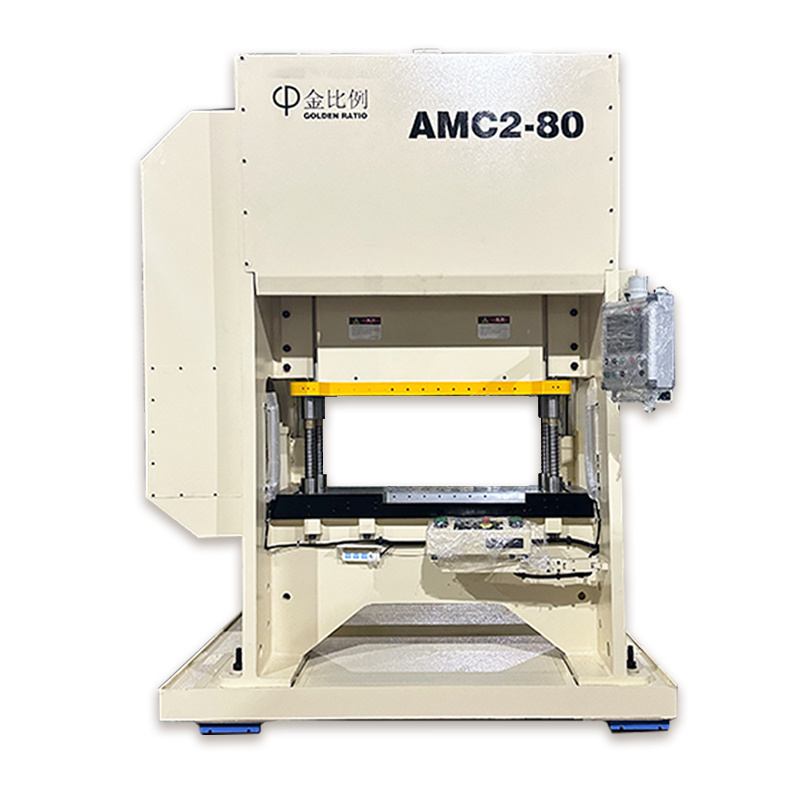

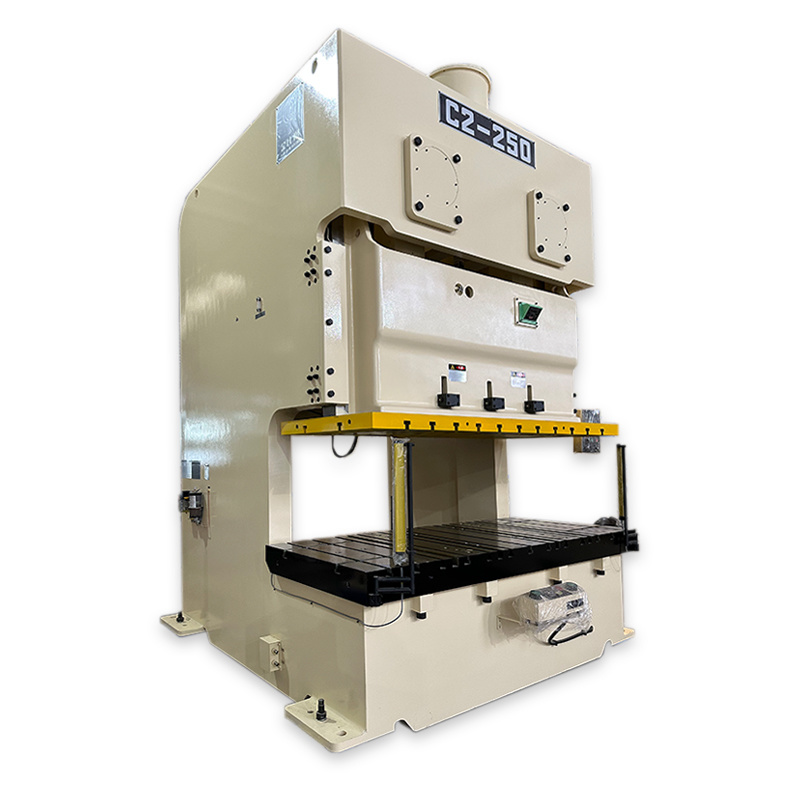

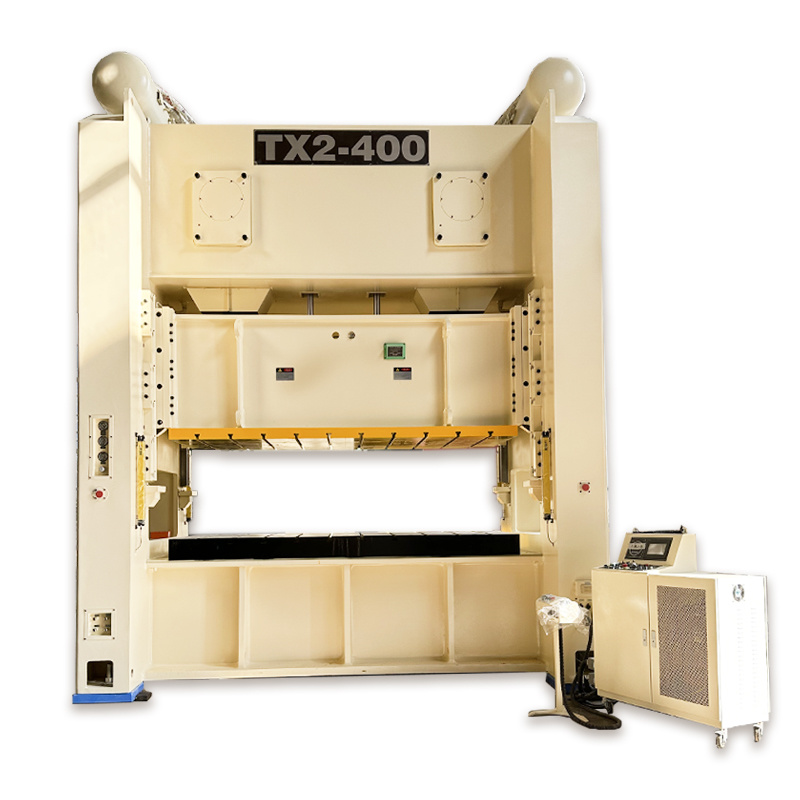

T1 Series

The company has automated cutting and welding equipment, large-scale processing equipment, painting equipment and testing equipment.

Classification:

T1 Series

Hotline:

Precision

Automation

Security

Stable

Energy saving

Environmental protection

- Product Features

- Configuration

- Parameters

- Size

- Download

-

Features

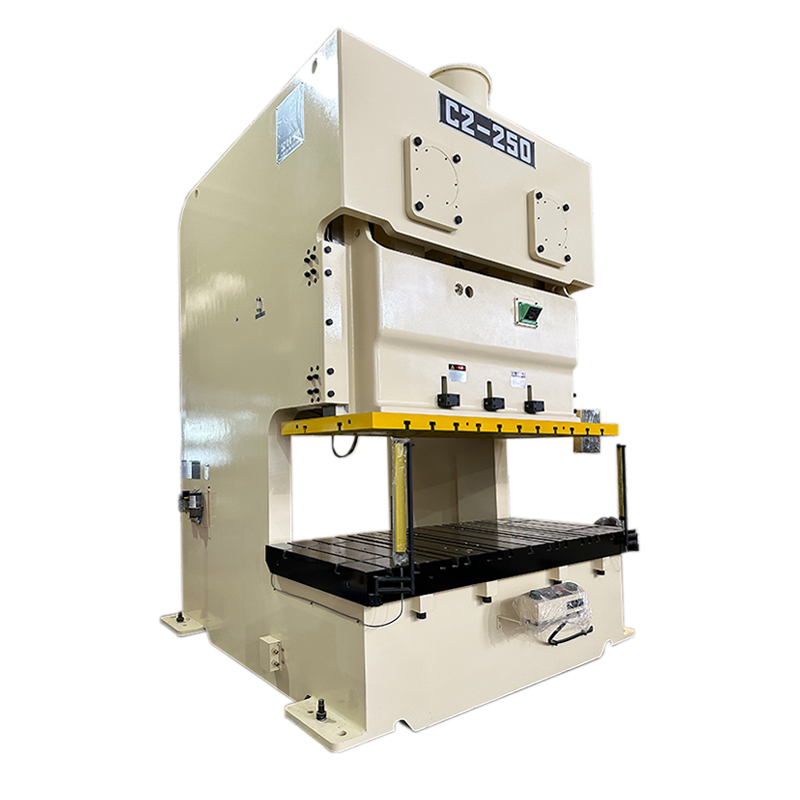

1. High rigidity frame design, the use of high-quality steel plate welding, after shot blasting treatment, after the elimination of internal stress treatment, to ensure stable accuracy;

2. The use of four corners and eight sides long guide rail, transmission structure of the reasonable design, to ensure the stability and precision of stamping.

3. Crankshaft, gear and other important parts, after tempering, grinding and other process processing, has excellent comprehensive performance.

4. With safe and reliable performance from the brake device and double solenoid valve, overload protection device. Ensure the normal operation of work and emergency stop in the production process and ensure the safety of personnel.

5. Variable frequency speed regulation can be carried out according to customer needs.

6. Adjust the height of different molds to meet more work needs.

7. Automatic lubrication system to ensure the normal work of the punch.

8. Compared with the C- type open punch, the closed type has the characteristics of high strength, high rigidity and high precision.

9. Can be matched with all kinds of peripheral equipment, improve production efficiency.

-

Standard configuration Select Configuration Hydraulic overload protection device Air pressure die pad device Frequency converter Quick mold change device (mold lift, mold clamp or mold transfer arm) Electric slide adjusting device Upper feeding device of slide block Electric die height display shockproof foot Slider and die balancing device Photoelectric protection device electronic cam switch Feeder (air, mechanical and NC types) crankshaft angle indicator Rack Air source connector leveler Preload counter Manipulator Pre-break counter Second degree fall protection device Maintenance tools and toolboxes Instructions for use Electric butter lubricating device Misinformed socket Mold lighting device -

Model Unit T1-160 T1-200 T1-250 T1-315 T1-400 T1-500 T1-630 Type Ton V-type Type L V-type Type L V-type Type L V-type Type L V-type Type L V-type Type L V-type Type L Long stroke mm 200 250 200 250 250 300 250 300 300 350 300 350 300 350 Number of trips S.P.M 20-50 20-40 20-50 20-40 20-40 20-35 20-40 20-35 20-30 15-25 20-30 15-25 20-30 15-25 Ability occurrence point mm 6 6 7 7 8 8 8 Closed working height mm 500 600 550 600 550 600 550 600 600 650 650 700 650 700 Slider adjustment amount mm 100 120 120 120 150 150 150 Area of upper table mm 700*650 900*800 900*800 1100*900 1000*900 1200*1100 1100*900 1300*1100 1100*1000 1400*1200 1200*1100 1400*1200 1400*1200 1500*1300 Area of lower table mm 900*800 1000*900 1000*900 1200*1000 1100*1000 1300*1200 1200*1000 1400*1200 1200*1100 1500*1300 1300*1200 1500*1300 1500*1300 1700*1500 Side opening size mm 700*500 700*500 700*500 700*500 900*600 900*600 900*600 900*600 900*600 1000*600 1000*700 1000*700 1100*700 1100*700 Main motor KW.4P 15*4 18.5*4 22*4 30*4 37*4 45*4 55*4 Height of working face (excluding shock absorbing pad) mm 900 950 1000 1000 1100 1200 900 (excavation pit) Maximum upper die weight kg 800 1000 1500 1500 2000 2500 2500

Previous Page

Related Products